Silicon Carbide

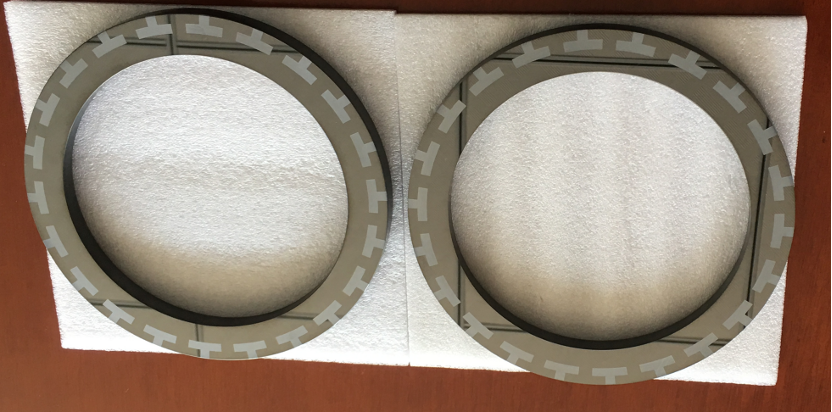

Mechanical Seals Seal faces

MGGS offers superior silicon carbide seal faces for various applications like oil refining, mining, automotive water pumps, chemical processing, pulp and paper processing, mixers, and refrigeration. These sealing materials include RB-SIC, SSiC, and SSiC+C. MGGS SiC products are an extremely hard and wear resistant material, it operates at temperature up to 1500℃ in diverse environments like corrosive, abrasive and so on.

Sintered Silicon Carbide and Reaction Bonded SiC Typical Physical Property Sheet

|

Property |

UNIT |

RB-SIC |

SSiC |

|

Density |

g/cm3 |

≥3.04 |

3.12~3.15 |

Hardness (Knoop) |

kg/mm2

|

1700

|

2600

|

Porosity |

% |

<0.3 |

<0.2 |

Compressive strengh @RT |

MpaX 103 Ib/ in2 |

>2200 |

>3000 |

|

Flexural Strength 4 pt@RT |

MpaX 103 Ib/ in2 |

>350 |

>450 |

Free-si content |

% |

8~12 |

<0.1 |

|

Purity(SIC content) |

% |

≥88 |

≥99 |

|

Modulus of Elasticity@RT |

Gpax106Ib/ in2 |

4.12×105 |

4.3×105 |

Poisson ratio |

|

0.15 |

0.15 |

Thermal Conductivity |

Cal/cm.s.℃ |

0.3 |

0.3 |

|

Coefficient of Thermal expansion RT to 700 ℃ |

I/℃ |

4.3×10-6 |

4.3×10-6 |

|

Maximum Service Temp. Air |

℃ |

1500 |

1600 |

Dry gas seal faces

MGGS can offer and supply superior quality Dry gas seal rings, we can make the spiral grooves with advanced and top technology and facilities and do the testings.